VMS Robotics

Milking that Revolves Around You

Robotic Milking marks a complete departure from Conventional Milking of any kind, basically removing the task of milking from the chore list. A common misconception, however, is that Robotic Milking is far less work than Conventional Milking, but in reality, while it might reduce the workload somewhat, the biggest help is that it makes it much easier to move tasks around and make time when necessary.

In other words, instead of milking cows two or three times a day, a dairyman or woman might instead be maintaining and cleaning the robotic equipment or fetching a few cows to go through the Robot. There’s still lots of work to be done, but most of the time it’s things that can be done now or later, so there’s time to run to town, meet with the vet or feed man, etc. For the right individual, Robotic Milking can mean lower stress, better family life, and a more efficient way to work.

Click here to take a virtual tour of a farm using the DeLaval VMS™ V300 Milking System

Benefits of Robotics Milking

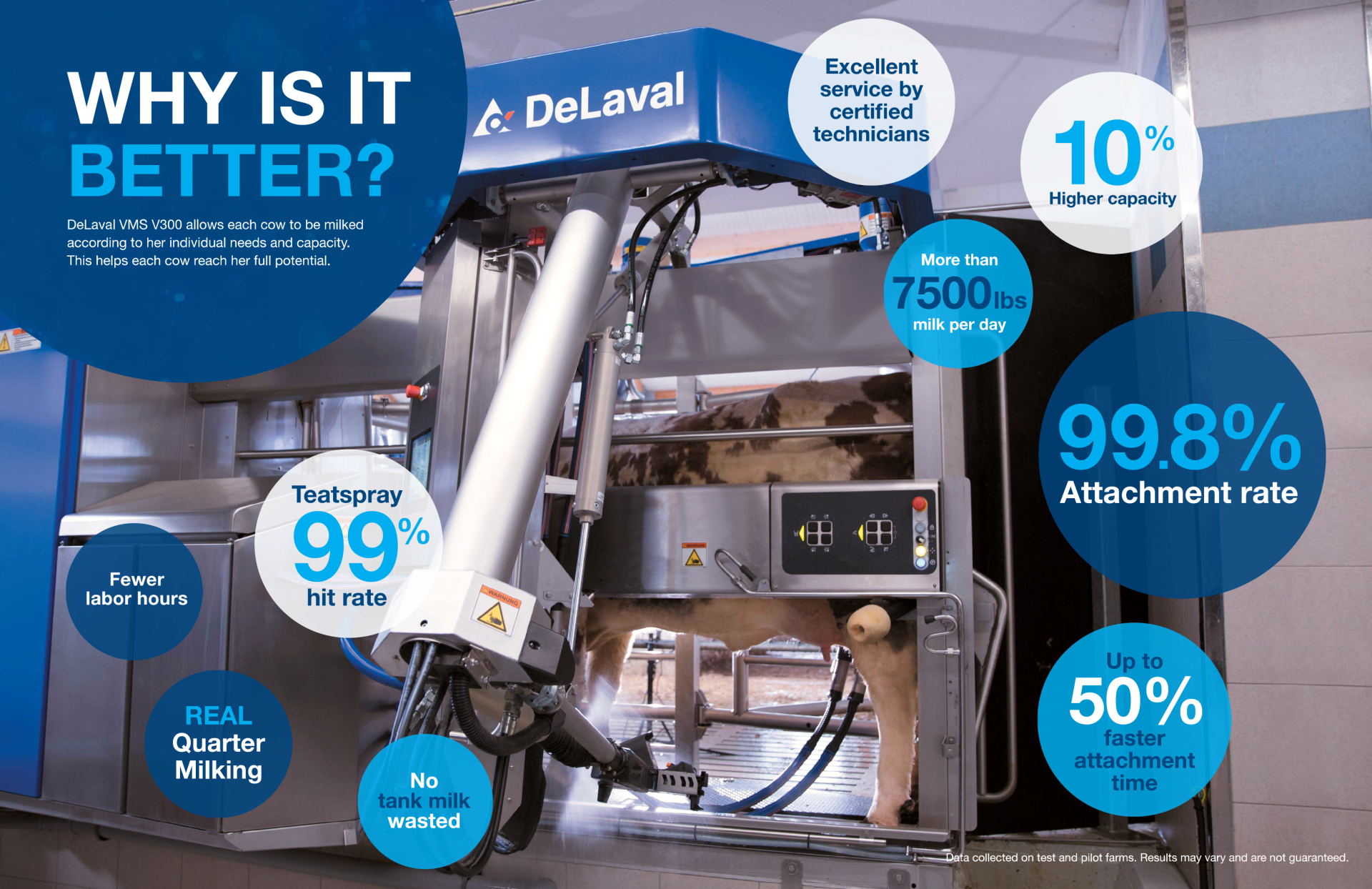

DeLaval leads the way in Robotic Milking Technology, and has done so for decades. DeLaval’s newest Robot, the VMS V300 boasts up to a 99.8% attachment rate, and 50% faster attachment speed compared with the previous model, the VMS Classic. The VMS V300 can milk up to 7,500 lbs. of milk per day; that’s 70 cows or more per Robot.

The VMS V300 is designed to maximize the economic benefit of every visit your cows make to it. It allows each cow to be milked according to her individual needs and capacity. This means that each cow is able to reach their full potential.

VMS V300 at a Glance

Take a Virtual Tour

Comestar Holsteins – 6 DeLaval VMS™ V300

Darita Holsteins– 2 DeLaval VMS™ V300

Jones Farm | DeLaval Robotics Virtual Tour

Greater Accuracy & Efficiency

DeLaval offers other Robotic Technologies for dairy farmers too, like the Teat Spray Robot (TSR) for Rotary Parlors and the Opti-Duo Robotic Feed Pusher. The TSR uses the same camera technology as the VMS V300 and is exceptionally fast and accurate as well as efficiently spraying only as much teat dip as each teat requires.

The TSR allows for one less person to be paid to watch those cows go around and around. The Opti-Duo Robotic Feed Pusher keeps feed fresh, alleys clean, and cows fed, so that the time spent doing this chore can be better utilized elsewhere.

The VMS™ Series is all about creating a better work environment and lifestyle for you and anyone who works on your farm.

Robotics systems are designed to help you generate more milk, more efficiently, more safely and more sustainably, in a way that also meets the consumer pressures that farmers the world over are facing today.

As a pure Voluntary Milking System, the VMS™ is not a conveyer belt that treats cows like products, it is a fully automated milking system that helps generate better results for you and your animals. Would you like to learn more? We invite you to contact us today.